As the brother of four sisters I learned a long time ago not to title a blog post something sexist like "Top Ten Gifts for Men", but let's be honest; this list is mostly going to appeal to men. And what's wrong with that? Let's face it, we can be tough to shop for. The following gift ideas would be welcomed the woodworker or Do It Yourselfer in your life, and unlike this silly pre-wrapped gifts for men, like the battery operated keyboard vacuum or a shiny new nose hair trimmer, these gifts will still be in use and be remembered for years to come.

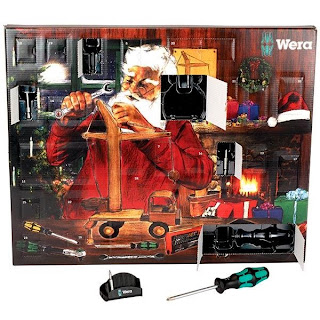

1.) Tool-Filled Advent CalendarThis gift is just amazing. Wera is a German hand tool manufacture that I've written about before, and for good reason: Their tools are excellent. They've done something so cool that I've decided to start my list with #1 instead of counting down from ten, because I just can't wait to share it with you: They have made a

Tool-Filled Advent Calendar that contains about $150 worth of tools for less than half that price!

Since the early 1800's Advent calendars have been a traditional way of counting down the 24 days leading up to Christmas, and while many of them have small daily gifts hidden behind small doors, I have never seen one that was made for tool fans! These are only available for a short time, so click the link and order yours today.

2.) Retro Shop StoolThe last thing most guys are gonna purchase for their shop is a chair or stool. Have you ever visited the shop and tried to find a place to sit and chat? It's not because you are unwelcome or that we couldn't make a stool; it's just that we are hard at work on your to-do list that we don't ever seem to get a round to it. And don't think that we wouldn't want to sit down! Just take a look at #3 for evidence of the need for more comfort in the shop.

This padded seat on this cool

Retro Shop Stool swivels 360 degree, and at 14" in diameter can comfortably support 350lbs.

3.) Back and Knee saving Anti Fatigue Floor MatHere's another simple gift idea that for some

Great Anti-Fatigue Mat at this link.

reason guys just don't think to buy for themselves. Every woodworker needs at least two of these in the spots where they find themselves standing the longest: Behind the workbench and either in front of the tablesaw or the lathe. If your woodworker isn't into wood turning (yet) than they may enjoy sawing on the scrollsaw or bandsaw, so I've got a great tip for you both. Position the mat with the short end against the wall and set the saw ON the mat. The mat will absorb vibration better than any anti-vibration pads that are sold for that purpose, and there will still be lots of room left for them to stand on the mat! Add this mat to the retro shop tool above and you will knock the socks off your loved-one. Find an inexpensive 2' X 5'

Anti-Fatigue Mat at this link, and a thicker, larger 3' X 5' and frankly,

all around more-better Anti-Fatigue Mat at this link.

4.) BESSEY Bar ClampsBessey is a German clamp manufacturer who makes the best clamps on earth. If you've ever watched Norm Abrams clamping anything on the New Yankee Workshop you've seen Bessey clamps in use. I use two different styles of Bessey clamps in my shop, and depending on what I'm building I'll reach for one or the other.

For assembling cabinets, tables and large furniture pieces I always reach for the classic

Bessey "K Body" clamps, which can be found at the link.

For assembling smaller items, such as gift boxes, jewelery boxes and nick-knacks, the right choice of clamp is the

Bessey F-Style clamp.

No, these aren't inexpensive gifts, but they will last a lifetime and will always work effortlessly. Something that will never be said about the cheap Chinese clamps that he's been settling with all these years.

5.) A Wood LatheAsk any woodworker what they would love to build if they had all the time, money and wood that they would need to accomplish it and most would say a Grandfather Clock. There's just something satisfying about the idea of building something beautiful and functional that will "live" long after we are gone. Now, ask a woodworker what tool they would love to master and 9 out of 10 of them will say the wood lathe. Why do so many of us want to learn to turn, and yet so few do? Because few of us own a lathe. And there's really not a good reason, because lathes have never been more affordable or as well made as they are today. Before gifting a lathe it is imperative to do a little spying to find out which size of lathe is appropriate. Small lathes are great for turning small objects like pens, candle sticks and parts for furniture (like that Grandfather Clock), while large lathes are needed for building parts for furniture like beds, chairs, tables, etc.

Here's a link to a great small lathe that would be perfect for a new turner who wants to turn pens gift items:

Rikon Mini LatheIf you're looking for a good starting lathe for turning furniture parts, take a look at this link:

Nova 1624-44 Wood LatheIf money is no option and you just want to cut to the chase and get one of the best lathes available, then I have no reservations in recommending the

Powermatic 4224B Wood Lathe. Even if you aren't in the market for a large lathe, you owe it to yourself to click on the link just to see how the other half turns!

6.) A Solid Beech WorkbenchThis is a tough one for me to put on a gift list, because I feel strongly that a craftsman owes it to themselves to build their own workbench. But the reality is few woodworkers will ever have the time or the money to make this dream a reality. In all candor it's actually more expensive to build a quality bench than it is to buy one, because bench manufacturers have the economy of scale working in their favor. Just like how you can never have enough clamps; you can never have too large or too heavy a workbench. My suggestion is to either buy the most expensive bench that fits your budget, or think about buying a gift card for a bench at Woodcraft. they sell a brand called Sjoberg that are very well made and are worth what they charge. Just one little reality check: Don't even consider a bench that sells for less than $500 because they will become firewood in fewer years than you can count on one hand. Buy

Sjoberg work benches here.

7.) Magnetic Shop LightYes, we did install a couple 4' florescent shop lights in our shop a couple years back, but they always seem to cast a shadow right were we need the light the most. This slick, portable shop light has a magnetic base that will also clip onto tools that feature plastic body parts. Buy this

Magnetic Shop Light at this link.

#8 DeWalt 13" Thickness PlanerI've owned this planer for about 5 years and besides my Shopsmith tools this is one of my two favorite power tool in my shop. In fact, this planer replaced my previous 12" DeWalt planer, which I was able to sell used on eBay for just about what I paid for it 5 years earlier! Woodcraft often offers this planer with either a free cover, stand or other useful do-hickey, so look around the site to make sure that this link is taking you to the best offer. Follow this link to the

DeWalt DW735X 13" Planer9.) Incra GaugeThis is hands-down my most reached-for tool in my shop. In fact, for less than $20 I have to say that if you buy nothing else on this list, buy this one! I'm fairly certain that this is going to be featured in one of my upcoming videos, because it's just such a handy tool. It's a marking gauge, a center finder, a height gauge for setting the height of your saw blade, dado blade and router bits and more. Just buy it. Buy the

Incra Gauge here.

And last, but not least...

10.) A Wooden WeWood Watch!This gift will THRILL the woodworker in your life, and there is no way that they would ever be able to make a wooden watch like this. They'll be able to wear a tangible symbol of their passion for wood, and will remember your thoughtfulness every time that look at it.

WeWood has been making fine timepieces for years and they even feature a 24 month warranty! Buy your

Wooden WeWood Wrist Watch at this link.

WeWood Watches offers a 24 month limited warranty on manufacturer defects. - See more at: http://www.woodcraft.com/Product/2084950/39890/WeWOOD-Men%27s-Date-Wooden-Watch-Beige.aspx#sthash.v1uvSL40.dpuf

WeWood Watches offers a 24 month limited warranty on manufacturer defects. - See more at: http://www.woodcraft.com/Product/2084950/39890/WeWOOD-Men%27s-Date-Wooden-Watch-Beige.aspx#sthash.v1uvSL40.dpuf

WeWood Watches offers a 24 month limited warranty on manufacturer defects. - See more at: http://www.woodcraft.com/Product/2084950/39890/WeWOOD-Men%27s-Date-Wooden-Watch-Beige.aspx#sthash.v1uvSL40.dpuf